Hydrotite waterstop exhibits exceptional integrity over time, even when exposed to significant hydrostatic pressure.

Excellent Durability

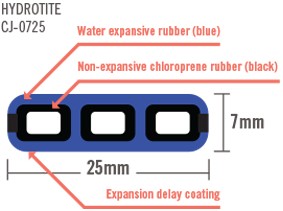

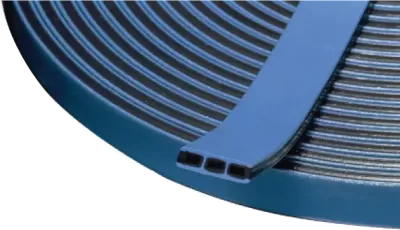

Hydrotite has been specifically designed and developed from synthetic rubber to provide excellent durability, improved resistance against long-term stress relaxation and microbial deterioration. The co-extruded profiles control the direction of expansion of Hydrotite across the joint, rather than along the path of least resistance, which ensures that higher contact surface pressures are achieved and improved water sealing results are maintained.

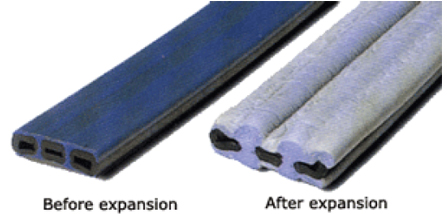

High Expansion Capacity

The high expansion capacity of Hydrotite provides an initial compression seal with reserve expansion capacity to accommodate future joint movement. The hydrophilic polymers are the best commercially available product. They swell up to 8x upon contact with water. Other hydrophilic waterstops provide lower volumetric expansion and do not accommodate future structural movement.

Hydrotite’s unique triple-action,

makes it superior to conventional water sealing materials:

1

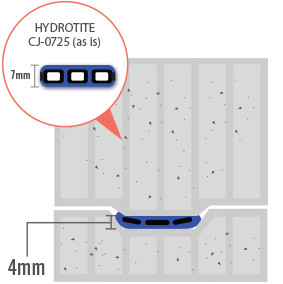

Initial compressed seal

The rubber elasticity and hollow core design provide an initial compressed seal between adjacent surfaces during construction.

2

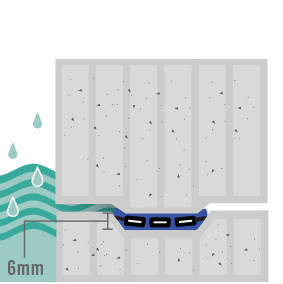

Hydrophilic reaction

The hydrophilic reaction produces secondary expansion following contact with water thereby ensuring a water-tight seal is maintained.

3

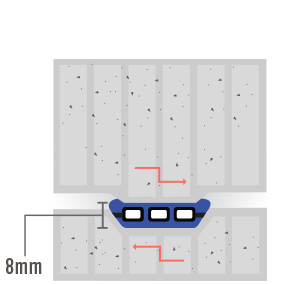

Residual expansion

In the event of future structural movement, Hydrotite provides residual expansion to ensure a high contact surface pressure and water tight seal is maintained. Read more