SUPERIOR MATERIAL PROPERTIES

AND PROVEN PERFORMANCE

Hydrotite is an industry-leading hydrophilic waterstops.

Premium Grade Material

Hydrotite is a synthetic rubber material that is manufactured from chloroprene rubber and a hydrophilic polymer. Chloroprene rubber materials are widely used in many industrial applications and are noted for their long-term durability. Hydrophilic polymers are selected to provide a safe and controlled expansion of the chloroprene rubber following contact with water. All Hydrotite profiles are supplied with a unique delay-action coating. This coating also allows concrete to develop initial strength before Hydrotite absorbs water and prevents any expansion taking place due to contact with fresh concrete. In addition, the delay coating allows Hydrotite to be exposed for short periods of time to adverse site conditions such as flooding, rain and snow. This eliminates the need to tear out and replace sections of waterstop due to premature swelling resulting from unforeseen circumstance. It is recommended that Hydrotite is scheduled for installation to minimize exposure to weather and, when possible, is protected from wet conditions. This unique delay coating is not available with any competitive hydrophilic materials.

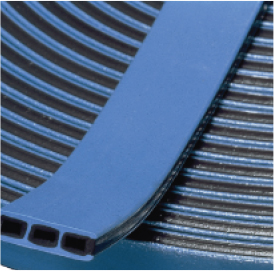

Co-Extruded Profiles

Hydrotite is the only hydrophilic products commercially available that feature a variety of co-extruded profiles, which consist of blue Hydrotite and black chloroprene rubber. The black chloroprene rubber is not hydrophilic and does not expand following contact with water. The primary feature of co-extruded profiles is to control the direction of expansion of Hydrotite across the joint, rather than along the path of least resistance. This ensures that higher contact surface pressures are achieved and improved water sealing results are maintained. Another benefit of co-extruding blue Hydrotite with black chloroprene rubber is to achieve more economical profiles.

Controlled Expansion

Blue Hydrotite has the capability to swell up to 8 times its original size upon contact with water. The extent to which this capacity is used is limited by the Hydrotite profile used, the availability of water and the space required to accommodate the expansion. This high expansion capacity provides a significant factor of safety for sealing construction joints. Due to design limitations, other commercially available hydrophilic sealing materials swell up to only twice their original size. This reduced expansion capacity, relative to Hydrotite, requires that large profiles be used, which are less effective when compared with the expansion capacity of blue Hydrotite.

Durability

Chloroprene rubber has been tested and found compatible with the following materials: aluminum chloride solutions, aluminum sulphate solutions, fluorosilicic acid, fuel oil, hydraulic oils, methyl alcohol and phosphoric acid. Its superior chemical resistance makes Hydrotite the ideal waterstop for curb joints in areas with hazardous materials.