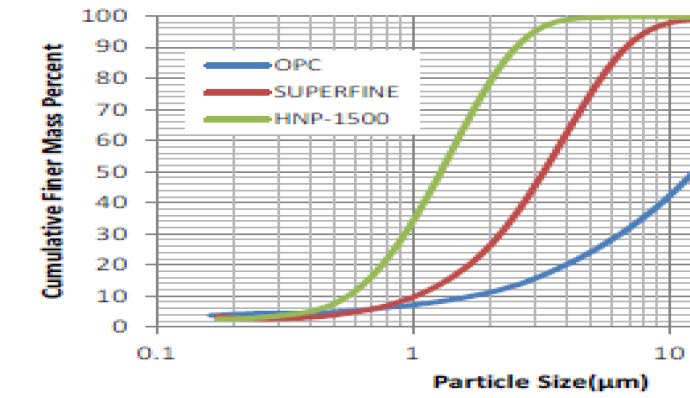

Microfine Cement (SuperFine) is an ultrafine blast furnace slag-based cement designed for specialty grouting applications. With a D95 particle size of 10 microns and a D50 particle size of 3 microns, it enables deep penetration into fine soil pores and microscopic rock fissures. This improves ground strength, reduces permeability, and enhances the effectiveness of water cut-off and consolidation grouting operations.

Key Features

-

Ultrafine Particle Size Distribution: Median size of 3 μm enables excellent penetration into fine soils and rock fissures.

-

High Strength and Durability: Produces grouts with strong in-place performance and long-term stability.

-

Adjustable Mix Design: Water/cement ratio and superplasticizer type/dosage can be tailored to meet specific project requirements.

-

Chemical and Brine Resistance: Performs reliably in aggressive environments, including those with high sulphate content.

-

Proven Field Performance: Backed by a long history of successful grouting projects in challenging conditions.

DOWNLOAD TECHNICAL LITERATURE

Product Data Sheet |

||

Safety Data Sheet |